Hazardous Sub-Project Early Warning Management System serves as an important tool for safeguarding construction safety. With multiple functions, it prevents and reduces the occurrence of major construction accidents.

The System enables the management and review of special construction plans for hazardous projects, thereby ensuring that the related preparation requirements are fulfilled prior to construction.

With the PC client and the app, the System enables on-site safety inspection management of high-risk engineering projects, and ensures that safety hazards are detected and dealt with in a timely manner.

The System monitors the safety conditions of key parts such as high-formwork supports and foundation pits through sensors to enable real-time monitoring, over-limit early warning and hazard alarming.

The System enables automatic collection of data such as pressure, settlement, displacement, and inclination angle, as well as real-time transmission via 4G/5G and GPRS wireless networks to ensure data authenticity, integrity, and timeliness.

Upon detecting a hazardous situation, the System is able to respond within one second and issue an audible and visual alarms to alert the operators to evacuate the hazardous area, and automatically notify the supervision personnel.

The System features emergency response functions to enable quick response and handling in the event of an accident, thereby minimizing the damage from the accident.

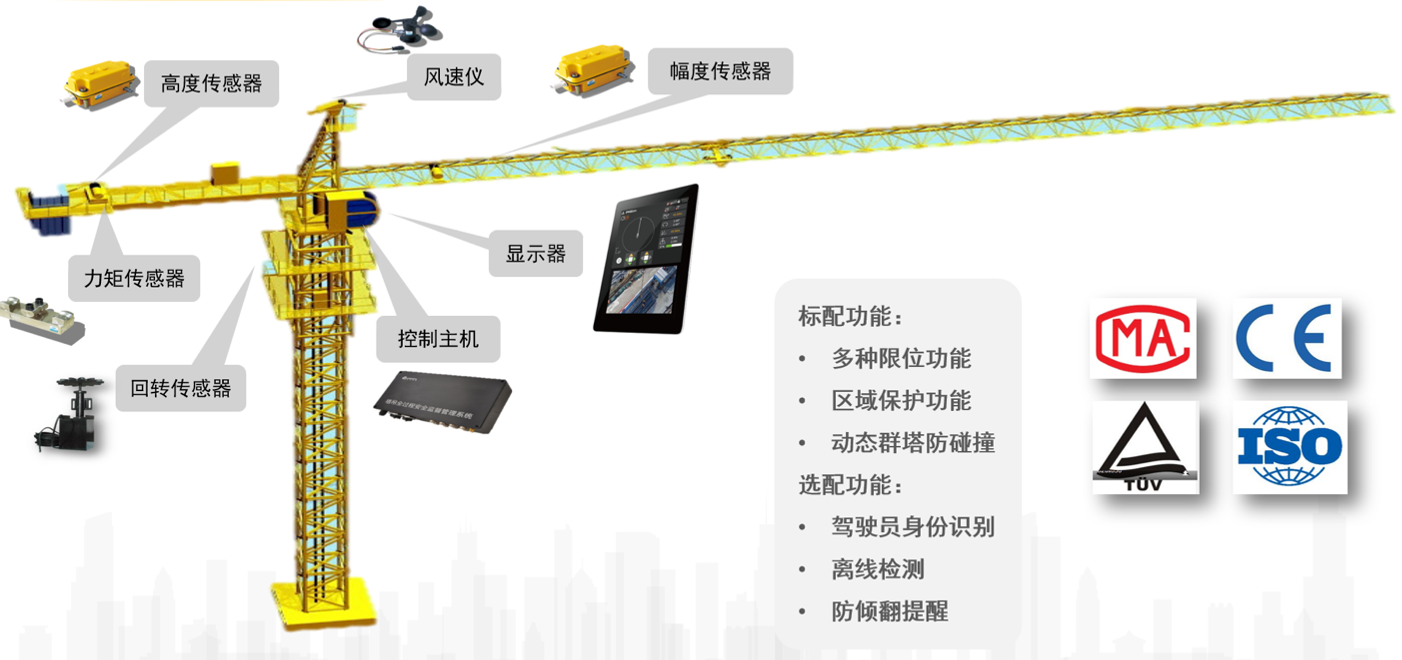

The Tower Crane Safety Monitoring Subsystem, also known as the “black box of the tower crane”, serves as a safety protection device for real-time monitoring of the working conditions of the tower crane.

Based on the working performance of different tower cranes, the System enables functions such as weight and torque limits, range, height, and slewing limits during tower crane operation, hazardous area prevention, and group tower operation collision avoidance, by monitoring the operating parameters of the tower crane in a real-time manner. A real-name system for personnel can be leveraged to manage tower crane drivers in a real-name manner, thereby preventing non-drivers of this Project from operating the tower cranes and avoiding accidents resulting from unsafe acts by personnel.

The System is an IoT system that enables management personnel to view data in a real-time manner from a remote location via a web platform. The application of the monitoring system enables real-time, remote monitoring of the safety conditions of tower cranes.

Tower Crane Driver Personal Identity Verification (PIV), a system used to ensure the safe operation of tower cranes, verifies the identity of the tower crane driver in a variety of methods to prevent unauthorized operation.

The System primarily addresses the potential safety risks of hoisting associated with the operation of tower crane driver, such as excessive height of the tower crane, blocked line of sight, unclear line of sight, etc. The position of the crane hook is dynamically tracked by installing a video camera on the crane boom. By monitoring the crane hook’s position on the screen directly, the driver can intuitively understand the working environment under the hook and proactively avoid collisions in the hook’s trajectory, thereby avoiding unnecessary safety risks.

The video images captured by the camera in the System can be wirelessly transmitted to a LAN and incorporated into the video surveillance system of the construction site, thereby achieving the dual functionality of one device.

Function of the hook visualization: To avoid operations in blind spots, reduce accidents during tower crane operations, accurately navigate the position of the hook at night, automatically zoom in on the camera to ensure clear images, and display the hook operation screen in the cab.

mark.ma@tengda.com.sg

+65 9352 9997

7030 ANG MO KIO AVE 5 #01-48 SINGAPORE 569880

Tengda Communications Technology Co., Ltd. (hereinafter referred to as “Tengda Communications”) is a provider of intelligent system engineering, information and communication network products and solutions.

Copyright © 2025 Tengda. All rights reserved. Powered by CARABOB Pte Ltd