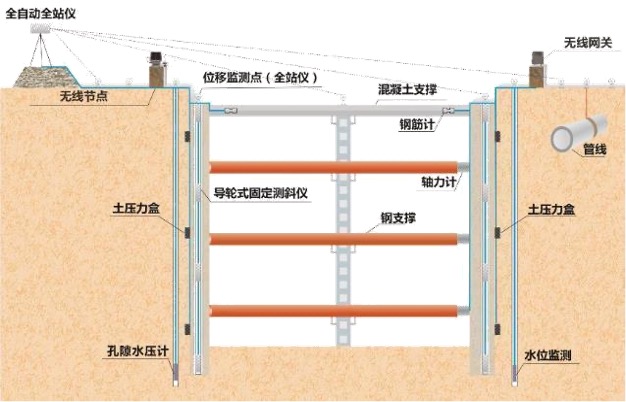

The System applies the IoT and mobile Internet technologies, and utilizes the layout plan and BIM model as the information carrier. Through the front-end sensors, the System enables real-time, all-weather monitoring of the horizontal displacement of the top of the support structure of the deep foundation pit, deep horizontal displacement, horizontal displacement of the top of the column, settlement, internal forces of the support structure, stress of the anchor cable, etc. All data are transmitted to the cloud for analysis, and an alarm will be triggered in the event of an exceedance of the warning threshold, thereby assisting in the safe management of foundation pits and preventing production safety accidents.

The Platform adopts a “1+2+N” model, where data management and analysis are unified via the command management platform. The Platform enables monitoring and collection of production factors with two viewing methods: web and mobile. Data information is interconnected in a real-time manner, facilitating decision-making and command by management personnel on project progress, personnel, materials, quality and safety, equipment, and production. The management can also stay on top of the overall project at anytime, anywhere.

Independently developed BIM lightweight engine technology, which can realize the digital twin of mechanical equipment, personnel management, and project progress during the construction process, and facilitate visual management and rational decision-making in the project department by means of virtual-real comparison and digital-analog linkage.

All bidding sections and key operational data are displayed on one screen, and the screen can be switched to a large screen for bidding with just one click. Meanwhile, various operational modules are displayed digitally separately, with more detailed content to satisfy various operational demands.

Information on production factors is interconnected and dynamically perceived in a real-time manner, facilitating scientific and reasonable scheduling and command by management personnel and supporting scientific decision-making.

The independently developed IoT platform enables 24h early warning of various hazards and risk points at all stages of construction, and it also enables full-cycle, all-round recording and tracing of construction quality, safeguarding the safety and quality of the projects.

mark.ma@tengda.com.sg

+65 9352 9997

7030 ANG MO KIO AVE 5 #01-48 SINGAPORE 569880

Tengda Communications Technology Co., Ltd. (hereinafter referred to as “Tengda Communications”) is a provider of intelligent system engineering, information and communication network products and solutions.

Copyright © 2025 Tengda. All rights reserved. Powered by CARABOB Pte Ltd